| C | Si | Mn | P | S | Cr | Mo | V |

|---|---|---|---|---|---|---|---|

| 0.30 - 0.40 | 0.80 - 1.25 | 0.20 - 0.60 | 0.03 | 0.03 | 4.75 - 5.50 | 1.25 - 1.75 | 0.20 - 0.50 |

H12 hot work Die Steel could be a five-hitter Cr, general hot work steel that is characterized by glorious impact toughness. It contains less vanadium than the widely-used H13 hot work tool steel, and also the tungsten content provides higher temper resistance. it has smart resistance to thermal fatigue cracking (heat checking) and excellent resistance to gross cracking and thermal shock once water cooled in commission.TLS H12 hot work tool steel is usually recommended for warm tooling applications wherever most resistance to cracking is needed. Such applications embrace hot punches, die casting dies, shaping dies, hot shear blades, hot gripper dies, and extrusion tooling.

General-purpose hot work steel with 4.75–5.5% chromium is known as AISI H12 tool steel. Vanadium content in H12 tool steel is (0.2–0.5%) lower than in the more popular H13 hot work tool steel (0.8–1.2%). A deep-hardening, air-hardening steel known as ASTM/AISI H12 experiences little size change following heat treatment. When water cooled in service, H12 tool steel material exhibits high resistance to gross cracking and thermal shock as well as good resistance to thermal fatigue cracking (heat cracking). Therefore, we may state that the following qualities best describe H-12 tool steel:

- Excellent resistance to wear, high strength at elevated temperatures.

- Good homogenizing with high toughness.

- Extra- fine- structure without grain-boundary carbide.

- Inclusion shape controlled with high cleanliness.

Virat Special Steels is the largest stockiest and supplier of H12 tool steel in flat, square and round bar. We provide steel in all sizes as your requirements. H12 die steel is available in flat, square and round shape. Consult our team who will assist you for H12 steel query.

Excellent Resistance to Wear, High Strength at Elevated Temperature with good Homogenizing with High Toughness. Extra- Fine- Structure without Grain-Boundary Carbide.

| Coefficient of thermal expansionat °C | 20-100 | 20-250 | 20-500 |

| 10-6 m/(m*K) | 11.7 | 12.4 | 12.9 |

| Thermal Conductivity at °C | 20 | 250 | 500 |

| W/(m*K) | 24.2 | 25.6 | 28.0 |

| Soft annealing °C | Cooling | Hardness HB |

|---|---|---|

| 820 | Furnace | max. 240 |

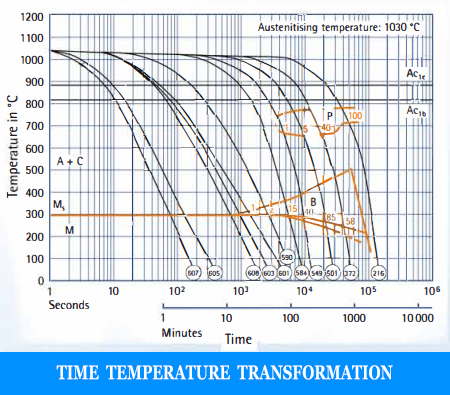

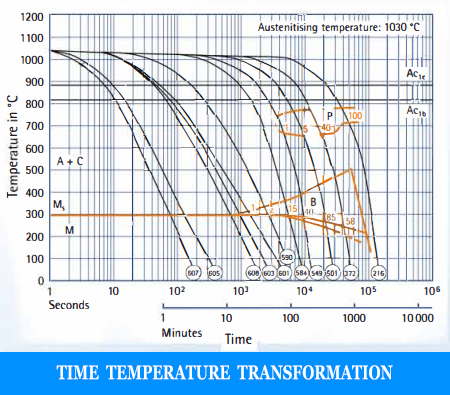

| Hardening °C | Quenching | Hardness after quenching HRC |

|---|---|---|

| 1030 – 1130 | Oil or hot bath, 500 – 550 °C | 57 |

| Tempering °C after Quenching | 100 | 200 | 300 | 400 | 500 | 600 | |||

| HRC | 55 | 54 | 54.3 | 54.8 | 53 | 51 | 48 | 41 | 34 |

This steel use for Forming dies, Press dies, Hot Shear, Immediate Roller for Cold Rolling.