| C | Si | Mn | P | S | Cr | Mo |

|---|---|---|---|---|---|---|

| 0.35 - 0.45 | 0.20 - 0.40 | 1.30 - 1.60 | 0.03 | 0.03 | 1.80 - 2.10 | 0.15 - 0.25 |

DIN 2311 is an alloy tool steel with good machining ability even when hardened and tempered (Brinell 300). This steel has a polished surface and is one of the most regularly used requirements for machine cut plastic molds and casting dies. DIN 2311 is frequently hardened and tempered, ready for machining. It provides great wear resistance in this form, however if maximal surface hardness is required for compression molding plastic dies or similar equipment, the steel can be case hardened. A higher Sulfur variant, DIN 2311, is offered for improved machinability.

Virat Special Steels is the largest stockiest and supplier of DIN 2311 Steel in flat, square and round bar. We provide steel in all sizes as your requirements. DIN 2311 die steel is available in flat, square and round shape. Consult our team who will assist you for DIN 2311 steel query.

P20 / DIN 2311 /AISI P20 is the Pre Hardened Plastic mould steel hardness distributed evenly in large cross sections that have excellent weldability with least hardness elevation, good mirror polishability and less streak texture making finishing easier. Size Section availability upto 255mm thickness. Supply hardness is 240-280 BHN.

| Tensile Strength | 965-1030 MPa |

| Yield Strength | 827-862 MPa |

| Hardness | 30 HRC |

| Elongation | 20% |

| Compressive Strength | 862 MPa |

| Elastic Modulus | 190-210 GPa |

| Coefficient of thermal expansionat °C | 20-100 | 20-150 | 20-200 | 20-250 | 20-300 | 20-350 | 20-400 | 20-450 | 20-500 |

| 10-6 m/(m*K) | 12.7 | 12.8 | 13.1 | 13.3 | 13.6 | 13.7 | 13.8 | 14.0 | 14.3 |

| Thermal Conductivity at °C | 23 | 150 | 300 | 350 | 400 | 500 |

| W/(m*K) | 32.0 | 32.8 | 31.4 | 30.2 | 29.6 | 27.5 |

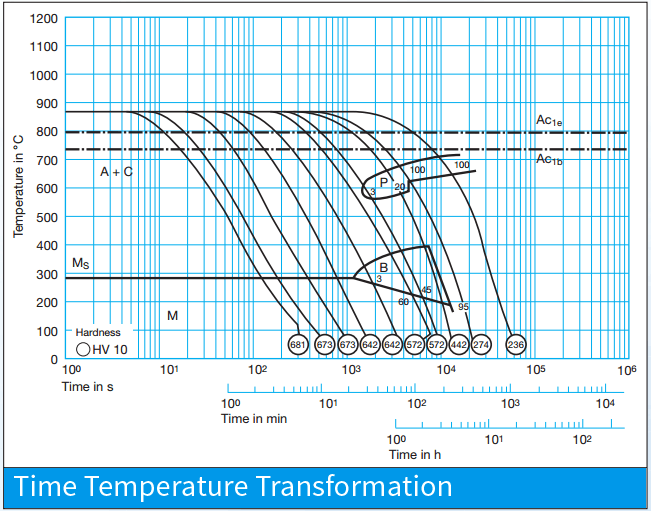

During the carburizing process, P20 / DIN 2311 / AISI P20 tool steels are heated to 871-899°C (1600-1650°F) in the carburizing medium. After carburizing, these steels are heated to 816-871°C (1500-1600°F) to harden, then held for 15 minutes before being oil quenched.

Heat the steel consistently to 820-840°C until completely heated. Soak in oil to cool.

Heat gently, giving the steel enough time to heat all the way through. start forging at 1050 degrees. Never forge below 930°C, reheating as needed. After forging, allow it to progressively cool.

To reduce machining stresses when dies are substantially machined, stabilizing is advised right before finishing machining. 460° to 500° Celsius. Good soaking followed by air cooling is advised.

Heating uniformly to 900°C for P20 / DIN 2311 / AISI P20 steel.

Heating consistently to 770–790°C for P20 / DIN 2311 / AISI P20 annealing. Good soaking, gentle cooling in the boiler.

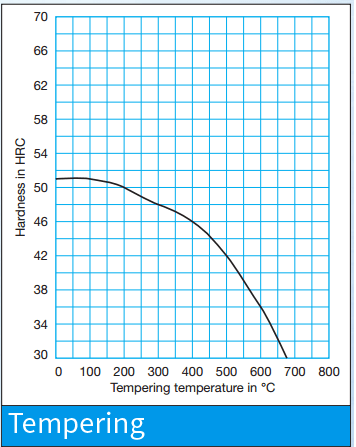

Heat evenly and soak for at least one hour for every 25mm of section at the tempering temperature. Allow it to cool in a cool air.

P20 / DIN 2311 / AISI P20 tool steels are welded using traditional techniques.

| Soft annealing °C | Cooling | Hardness HB |

|---|---|---|

| 710 – 740 | Furnace | max. 235 |

| Hardening °C | Quenching | Hardness after quenching HRC |

|---|---|---|

| 850 – 880 | Oil or saltbath, 180 – 220 °C | 52 |

| Tempering °C after Quenching | 100 | 200 | 300 | 400 | 500 | 600 | 700 |

| HRC | 52 | 50.5 | 48.5 | 46 | 42 | 36.5 | 28 |

Plastic mould steel equivalent to P20/ DIN 2311 / AISI P20 use for die holders, zinc die, casting dies, backers, bolsters, injection moulds, mould frames for plastic moulds, Shoe Blocks, pressure casting moulds, recipient sleeves Etc.