| C | Si | Mn | P | S | Cr | Mo | V |

|---|---|---|---|---|---|---|---|

| 1.50 - 1.60 | 0.10 - 0.40 | 0.15 - 0.45 | 0.03 | 0.03 | 11.0 - 12.0 | 0.60 - 0.80 | 0.90 - 1.10 |

Virat Special Steels is the leading Supplier & Stockiest of Din 2379 (X153CrMoV12) Steel.

Din 2379 Consolidates maximum wear resistance, great durability, exceptional front line maintenance and treating resistance 12 % ledeburitic chromium steel. It can be nitrided after special heat treatment.

It can be utilized as threading rolls and dies, icy trimming, cutting and stamping tools for sheet thickness's up to 6 mm, accuracy cutting instruments for sheet thicknesses up to 12 mm.

DIN 2379 steel is a high-carbon, high-chromium & air-hardening tool steel. It is extremely wear- and abrasion-resistant. It is machinable in the annealed condition and may be heat treated to a hardness of between 55 and 62 HRC. On proper hardening, DIN 2379 steel exhibits low deformation. Due to its high chromium content, hardened DIN 2379 steel has a modest ability to resist corrosion. DIN 2379 tool steel has good corrosion resistance when polished and hardens in air. Frequently used for tools that operate in harsh wear-and-tear environments or as an alternative to oil-hardening tool steel grades when lengthy runs are necessary.

Virat Special Steels is the largest stockiest and supplier of DIN 2379 Steel in flat, square and round bar. We provide steel in all sizes as your requirements. DIN 2379 die steel is available in flat, square and round shape. Consult our team who will assist you for DIN 2379 steel query.

DIN 2379 steel is Cold Work Steel with High Carbon High Chromium contents. The Quality with high wear resistant and toughness properties due to Vanadium addition of 0.90% . Normally it supply condition is an Annealed and will offer hardness to reach 57-59 HRC. It can be machinable in the annealed condition.DIN 2379 is the superior steels than D3 due to high alloys properties.

| Impact Toughness | 77 J/cm2 |

| Hardness | 62-63 HRC |

| Poisson’s Ratio | 0.27-0.30 |

| Modulus of elasticity | 190-210 GPa |

The physical properties can vary slightly depending on the specific composition and heat treatment of the D2/ DIN 2379/ AISI D2 steel. Its always recommended to refer to the manufacturer’s specifications for precise information.

| Coefficient of thermal expansionat °C | 20-100 | 20-200 | 20-300 | 20-400 |

| 10-6 m/(m*K) | 10.6 | 11.5 | 11.8 | 12.3 |

| Thermal Conductivity at °C | 20 | 350 | 700 |

| W/(m*K) | 16.7 | 20.5 | 24.2 |

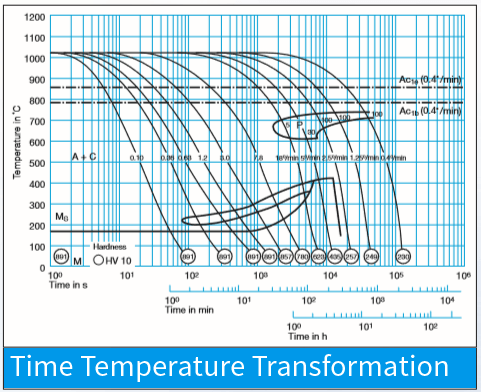

The heat treatment Process includes parameters like temperatures, the rate of heating, cooling, soaking time ,the type of furnace, quenching medium, and workpiece transfer facilities.

Allow the D2/ DIN 2379/ AISI D2 tool steel to soak at 750-800°C after preheating it. The tools are then heated to 1000-1040°C for air cooling and 980°C for oil quenching. Soak for thirty minutes per 25mm of the ruling part at the temperature, then cool or quench as needed. When heating for hardening, it is critical not to surpass 1040°C.

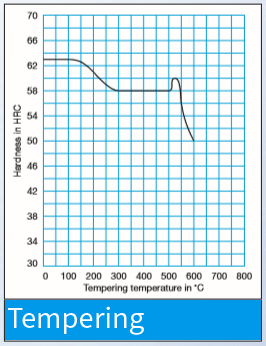

Tempering of D2/ DIN 2379/ AISI D2 tool steel should be done with the least possible delay after hardening, preferably when the tools still hand warm. Double tempering is recommended. Heat slowly and uniformly. When the D2/ DIN 2379/ AISI D2 has reached the desired temperature, soak for at least one hour per 25mm of section. The second tempering should be a repetition of the first.

The Stress relief must be done after rough machining. To stress relief, heat the component to approx. 600-650°C in the case of D2/ DIN 2379/ AISI D2 steel. Then it should be Soaked well and cooled in the furnace or in the air.

D2/ DIN 2379/ AISI D2 steel normalizing process should be avoided because there are chances of distortion due to stress with faster cooling .

It is necessary to heat gently and consistently to 900°C for the annealing of D2/ DIN 2379/ AISI D2 steel. Then it must soak for three to four hours before cooling in the furnace till room temperature. Reheat to 800–1040°C, then soak for another three–four hours. Allow the furnace to drop to room temperature.

The metal should always be welded in the annealed or hardened condition always. Hence, it should be used with lowest possible weld current, Peen each weld after completion, ensure parts are clean. Avoid excess joint restraints.

| Soft annealing °C | Cooling | Hardness HB |

|---|---|---|

| 840 - 870 | Furnace | max. 250 |

| Stress-relief annealing °C | Cooling |

|---|---|

| approx. 660-710 | Furnace |

| Hardening °C | Quenching | Hardness after quenching HRC |

|---|---|---|

| 1000-1050 | Air, oil or saltbath, 500-550 °C | 63 |

| Tempering °C after quenching | 100 | 200 | 300 | 400 | 500 | 525 | 550 | 600 |

| HRC | 64 | 61.5 | 58.5 | 58.5 | 59 | 60 | 57 | 50 |

DIN 2379 tool steel applicable for cold stamping or forming dies, cold forming rolls, Chipper knives, Punches, slitters, shear blades, tools, tyre shredders, trimming, cutting Threading Dies , stamping tools Etc.