| C | Si | Mn | P | S | Cr | Mo | V |

|---|---|---|---|---|---|---|---|

| 0.26-0.36 | 0.15-0.50 | 0.15-0.40 | 0.03 | 0.03 | 3.00-3.75 | - | 0.30-0.60 |

Virat Special Steels is the biggest Supplier and Stockiest of Hot Work Steel AISI H21.

AISI H21 is a hot work tool steel for oil or air solidifying to grow high hot quality, maintenance of hardness and warmth checking resistance.

This is mostly utilized as hot work devices, instruments for manufacture of hollows, screws, rivets, nuts and bolts. Die casting tools, forming dies, die inserts, hot shear blades.

Tungsten hot-work steels are classified into AISI H21 to AISI H26 grades. These steels have properties similar to high-speed steels. Tungsten, chromium, carbon, and vanadium are the principal alloying components in tungsten hot-work steels. When air-hardened, they are less prone to deformation and have a greater hardening temperature than chromium hot-work steels. Preheating tungsten hot-work steels to operating temperature before use helps prevent breakage. By lowering the carbon content, these steels' thermal shock resistance and hardness may be increased. This is mostly utilized as hot work devices, instruments for manufacture of hollows, screws, rivets, nuts and bolts. Die casting tools, forming dies, die inserts, hot shear blades.

Virat Special Steels is the largest stockiest and supplier of AISI H21 tool steel in flat, square and round bar. We provide steel in all sizes as your requirements. AISI H21 die steel is available in flat, square and round shape. Consult our team who will assist you for AISI H21 steel query.

Hot work steel with good toughness include tungsten Chromium Carbon Vanadium usually is working hardness is 40.0 to 55.0 HRC size available in round, flat and square.

| Hardness | 40-55 HRC |

| Modulus of elasticity | 190-210 GPa |

Depending on the precise composition and heat treatment of the H21/ DIN 2581/ AISI H21 steel, the physical attributes may differ somewhat. Its always advisable to refer to the manufacturer’s specifications for accurate information.

| Coefficient of thermal expansionat °C | 20-100 | 20-200 | 20-300 | 20-400 | 20-500 | 20-600 | 20-700 |

| 10-6 m/(m*K) | 11.2 | 11.9 | 12.2 | 12.5 | 12.8 | 13.0 | 13.2 |

| Thermal Conductivity at °C | 100 | 400 | 675 |

| W/(m*K) | 27.0 | 29.8 | 29.1 |

The tungsten percentage in H21/ DIN 2581/ AISI H21 steels makes them harder to manufacture when compared to water hardening low alloy steels, which have 100% machinability whereas H21/ DIN 2581/ AISI H21 has 55%.

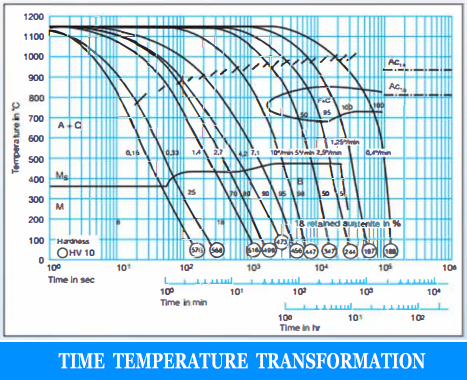

The H21/ DIN 2581/ AISI H21 steels must be warmed to 816°C (1500°F) and then quickly heated to 1177°C (2150°F) for this procedure. The steels should then be kept at the same temperature for 2 to 5 minutes before being air cooled or oil quenched.

H21/ DIN 2581/ AISI H21 steel Forging is performed at 1150°C (2100°F) down to 927°C (1700°F) but not below 899°C (1650°F).

Annealing of H21/ DIN 2581/ AISI H21 tool steel is performed at 885°C (1625°F) followed by slow furnace cooling at a temperature less than 4°C (40°F) per hour.

Cold working may be carried out on H21/ DIN 2581/ AISI H21 tool steels using conventional methods.

H21/ DIN 2581/ AISI H21 tool steels may easily be welded using a variety of welding techniques.

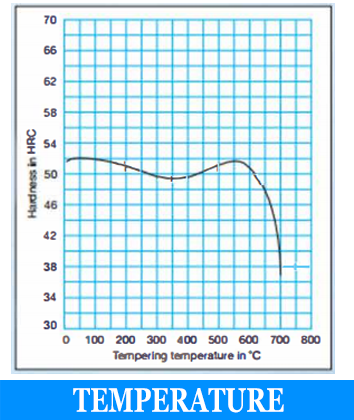

Tempering the H21/ DIN 2581/ AISI H21 steels at 593 to 677°C (1100 to 1250°F) results in a 54 to 36 HRC. A double tempering procedure is recommended, and the pieces should be kept at the same temperature for one hour.

| Soft annealing °C | Cooling | Hardness HB |

|---|---|---|

| 780 – 810 | Slowly | max. 240 |

| Hardening °C | Quenching | Hardness after quenching HRC |

|---|---|---|

| 1000 – 1130 | Oil or hot bath, 600 – 650 °C | 53 |

| Tempering °C after Quenching | 100 | 200 | 300 | 400 | 500 | 550 | 600 | 650 | 700 |

| HRC | 49 | 49 | 49 | 49 | 51 | 51 | 50 | 46 | 36 |

The AISI H21 tungsten hot-work tool steels are mainly used for hot-working dies and toolings, e.g., die casting, extrusion and hot-forming of parts.