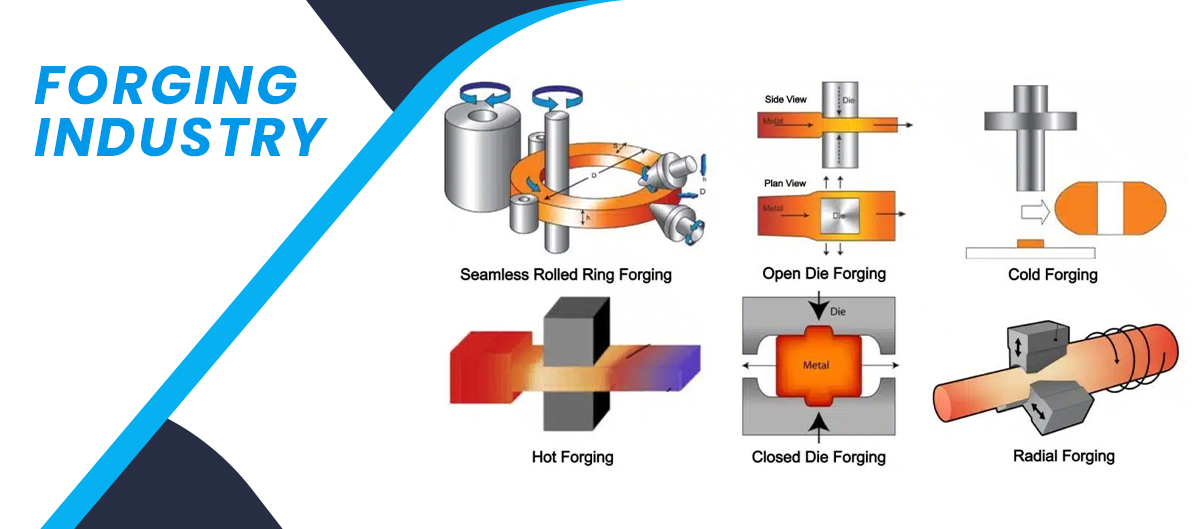

Forging is a process in which metal is being shaped using compressive forces with a Hammer or a press. Forging are classified into Cold forging, warm forging or hot forging.

Mainly material used: - DIN 1.2714 (DB6), DIN 1.2344 (H13), DIN 1.2343 (H11).

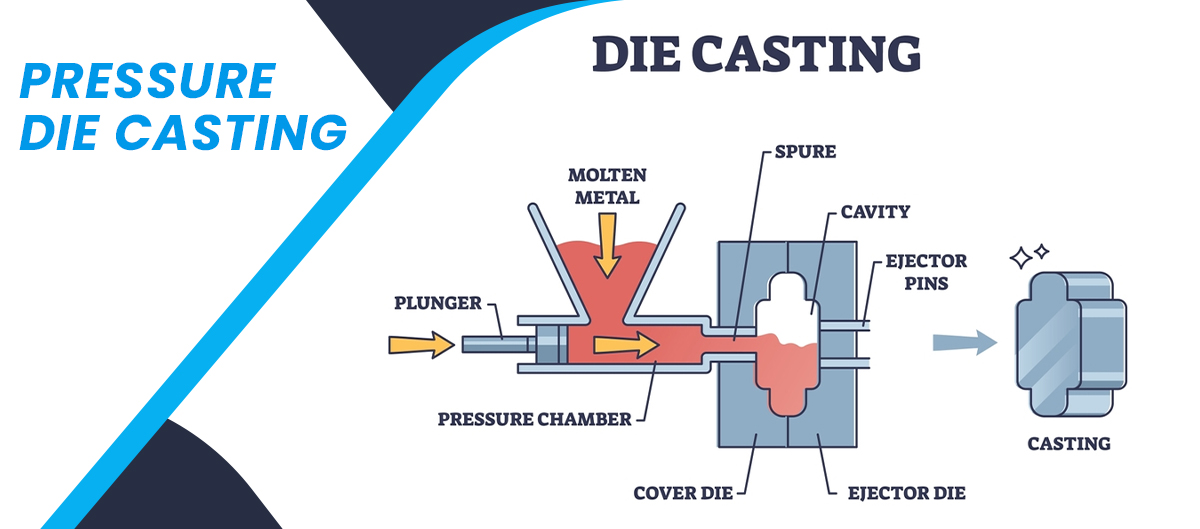

Die casting is performed by forcing molten metal under high pressure into a mold cavity & the cavity (mold cavity) is manufacture by using two hardened tool steel dies & perform similar to an injection mold.

Mainly material used: Hot die steel i.e. DIN 1.2344 (H13), DIN 1.2343 (H11), and DIN 1.2581 (H21).

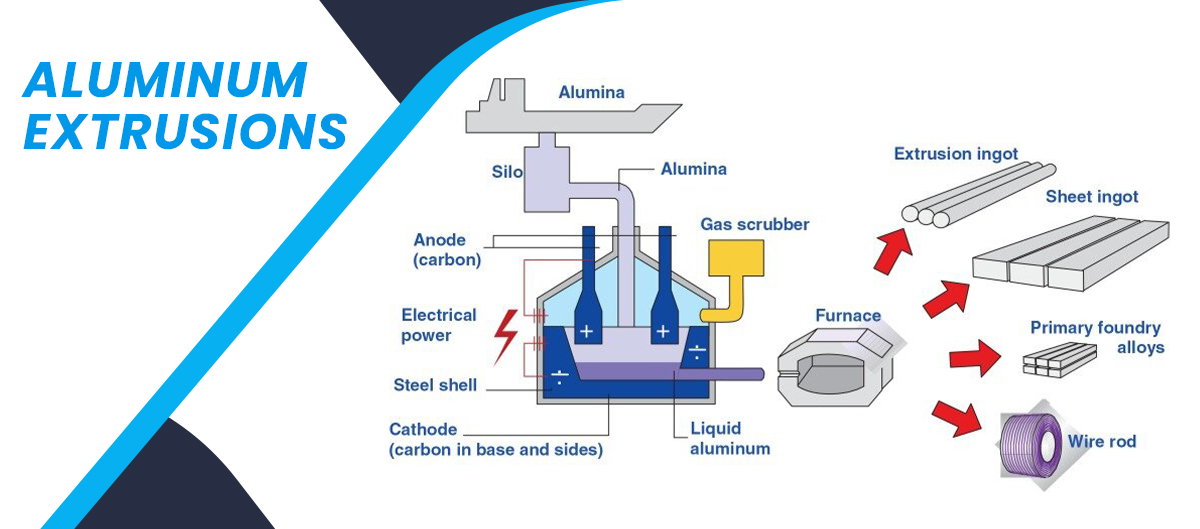

In Extrusion process material is pushed through a die to the desired cross section & in this manufacturing process it creates very complex cross section. The parts are being formed with an excellent surface finish.

Mainly material used: - Hot die steels i.e. DIN 1.2344 (H13) grade.

Automotive industry are wide range of companies is mainly involved in manufacturing, design, development, of motor vehicles.

Mainly material used: - DIN 1.2714 (DB6), 40niCrMo84 (EN24), DIN 3343(M2 ), 16MnCr5 , 20MnCr5 .

Oil & Gas they supply more than 60 percent of our nation’s energy. Natural gas also helps generate the electricity that powers our daily lives.

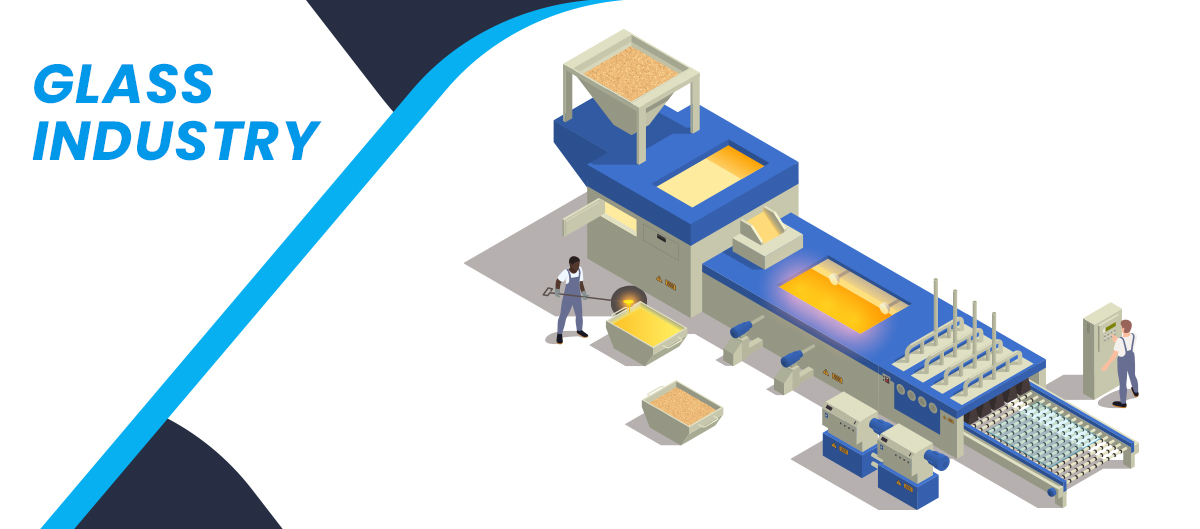

Glass industry mainly involves in glass production. There are two main methods of manufacturing i.e. float glass process (produces sheet glass) & Glassblowing (produces bottles and there containers).

Cycle parts companies are mainly involves in manufacturing components like Bearing, chain, chain sets& cranks, handlebars, forks.

Mainly material used:- DIN 1.2714 (DB6), DIN 1.2344(H13), DIN 1.2343 (H11).

They are involves mainly in manufacturing railways components i.e. Railway gear holder, Railway bogie cast parts, Railways axles, railways Sets of pins, Ground lever frame, adjustable crank, Compressor pistons, Compressor bearings.

Mainly material used:-DIN 1.2714 (DB6), DIN 1.2344(H13), DIN 1.2343 (H11), DIN 40niCrMo84 (EN24), 20NiCrMo5 (EN353 ).