| C 0.10-0.20 | Si 0.35 | MN 0.50-1.00 | Cr 0.75-1.25 | Mo 0.80-0.15 | NI 1.00-1.50 |

Virat Special Steels is the biggest & leading Supplier & Stockiest of EN353 Steels.

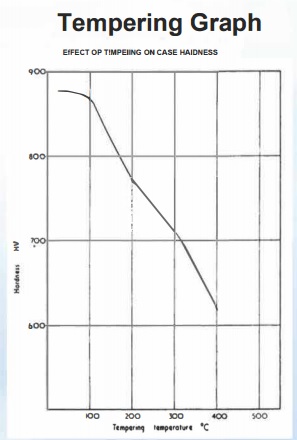

EN 353 steel has carbon content material of 0.17 % & probably the most usual form of steel, because the carbon content material raises, the material becomes tougher & harder. It's observed that the hardness & wear resistance of the EN 353 steels elevated after the warmness therapy & the micro structure is exchange from ferrite to marten website.

This grade is in general used for a lot of automobiles functions comparable to heavy duty tools, shaft, pinion, cam shafts and gudgeon pins.

En 353 steel has a carbon content of 0.17% and the commonest form of steel as it provides material properties that are acceptable for several automobile applications such as significant duty gear, shaft, pinion, camshafts and gudgeon pins. It’s neither outwardly brittle nor ductile due to its lower carbon content and lower hardness. Because the carbon content will increase, the metal becomes more durable and stronger.

| Thermal Conductivity at °C | 20 | 350 | 700 |

| W/(m*K) | 11.3 | 13.3 | 14.5 |

Acceptable for many automobile applications such as heavy duty gear, shaft, pinion, camshafts, gudgeon pins. / Machining components.

| Soft annealing °C | Cooling | Hardness HB |

|---|---|---|

| 630-670 | Furnace | max. 270 |

| Stress-relief annealing °C | Cooling |

|---|---|

| 150-200 | Furnace |

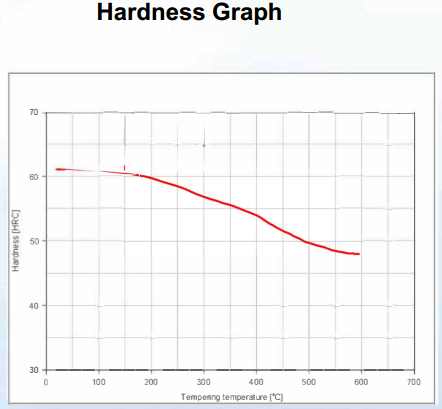

| 1st pre-heating °C | 2nd and 3rd | Hardening °C | Quenching | Tempering °C | Hardness after Teperature HRC |

|---|---|---|---|---|---|

| up to approx. 400 in an air-circulating furnace | 780 and 850 | 780-820 | 810 °C Oil ,Quench | at least twice 150-200 | 62 – 64 |