+91-98140 21775

info@viratsteels.com

| C 0.20 | Si 0.80 | Mn 1.70 | S 0.010-0.015 | P 0.020-0.025 | Cr 1.50 | Mo 0.70 | NI 2.0 | Ti 0.05 | Zr 0.15 | Cu 0.50 | Nb 0.06 | V 0.12 |

Virat Special Steels is the leading provider & Stockiest of AISI 8620 Steel.

AISI 8620 is a hardenable chromium, molybdenum, nickel low alloy steel more often used for carbonizing to advance a case-hardened phase. This case-hardening will influence in just right wear traits.

This Grade is in most cases used for gears, ring gears, shafts and crankshafts.

8620 is a hardenable chromium, molybdenum, nickel low alloy steel often used for carburizing to develop a case hardened part. This case-hardening will result in good wear characteristics.

| Thermal Conductivity at °C | 20 | 350 | 700 |

| W/(m*K) | 46.0 | 46.2 | 46.4 |

Application- Gears, shafts and other applications where a hard carborized case and a tough core are desired.

| Soft annealing °C | Cooling | Hardness HB |

|---|---|---|

| 820-850 | Furnace | max. 290 |

| Stress-relief annealing °C | Cooling |

|---|---|

| 630-650 | Furnace |

| 1st pre-heating °C | 2nd and 3rd | Hardening °C | Quenching | Tempering °C | Hardness after Teperature HRC |

|---|---|---|---|---|---|

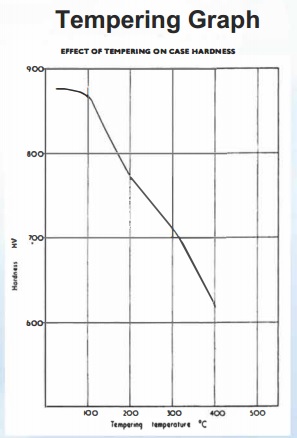

| up to approx. 400 in an air-circulating furnace | 780 and 850 | 840-870 | 810 °C Oil ,Quench | at least twice 150-200 | 62 – 64 |