+91-98140 21775

info@viratsteels.com

| C 0.90-1.20% | Si 0.10-0.35% | MN 0.30-0.75% | S 0.050% max | P 0.050% max | Cr 1.00-1.60% |

Virat Special Steels is the biggest & leading Supplier & Stockiest of 100Cr6.

EN 31 is an excellent high carbon alloy steel which offers a high measure of hardness with compressive strength and abrasion resistance.

This Grade is quite often used for wear resisting machine constituents and for press instruments which don't advantage an extra complex satisfactory.

Standard hiqh-speed steel qrade. Itswell-balanced alloy composition forms the basis of its high_touqhn-essand good clllting edge retention, rendenng it $uitable for a large variety of appllcatons.

| Thermal Conductivity at °C | 20 | 350 | 700 |

| W/(m*K) | 44.5 | 45.0 | 46.0 |

Acceptable for many automobile applications such as heavy duty gear, shaft, pinion, camshafts, gudgeon pins. / Machining components.

| Soft annealing °C | Cooling | Hardness HB |

|---|---|---|

| 780-800 | Furnace | max. 207 |

| Stress-relief annealing °C | Cooling |

|---|---|

| 600 - 650 | Furnace |

| 1st pre-heating °C | 2nd and 3rd | Hardening °C | Quenching | Tempering °C | Hardness after Teperature HRC |

|---|---|---|---|---|---|

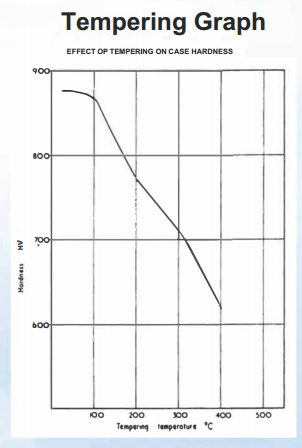

| up to approx. 400 in an air-circulating furnace | 800 and 900 | 800-820 | 810 °C Oil ,Quench | at least twice 150-200 | 61 – 63 |