| C 0.14 - 0.19 | Si max 0.4 | MN 1 - 1.3 | S max 0.035 | P max 0.025 | Cr 0.8 - 1.1 |

Virat Special Steels is the biggest Supplier & Stockiest of 16MnCr5 Steel.

16MnCr5 Steel contains smooth, deformable calcium aluminates encapsulated in manganese sulphide as an alternative than tough alumina oxide inclusions. Calcium treated metal for Inclusion amendment.

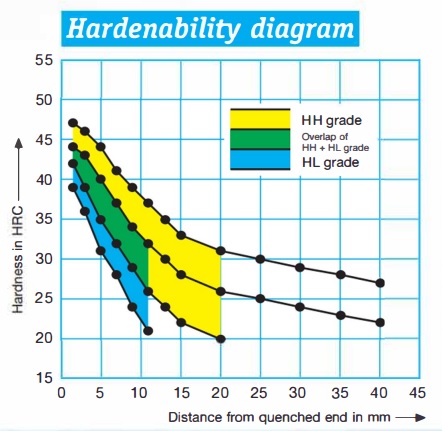

Tightly managed harden potential managed analysis for repeatable strength and fatigue homes.

This Grade is generally used for elements with a required core tensile strength of 800 – 1100 N/mm² and good carrying resistance as piston bolts, camshafts, levers and other automobile and mechanical engineering add-ons.

16MnCr5 Steel Grade is generally used for elements with a required core tensile strength of 800 – 1100 N/mm² and good carrying resistance as piston bolts, camshafts, levers and other automobile and mechanical engineering add-ons.

| Thermal Conductivity at °C | 20 | 350 | 700 |

| W/(m*K) | 44.5 | 45.0 | 46.0 |

Application- Alloyed case hardening steel for parts with a required core tensile strength of 800 - 1100 N/mm² and good wearing resistance as piston bolts, camshafts, levers and other vehicle and mechanical engineering components.

| Soft annealing °C | Cooling | Hardness HB |

|---|---|---|

| 650-700 | Furnace | max. 206 |

| Stress-relief annealing °C | Cooling |

|---|---|

| 600-620 | Furnace |

| 1st pre-heating °C | 2nd and 3rd | Hardening °C | Quenching | Tempering °C | Hardness after Teperature HRC |

|---|---|---|---|---|---|

| up to approx. 400 in an air-circulating furnace | 740 and 840 | 810-840 | 870 °C Oil ,Quench | at least twice 150-200 | 62 – 64 |